- Home

- About

- Products

-

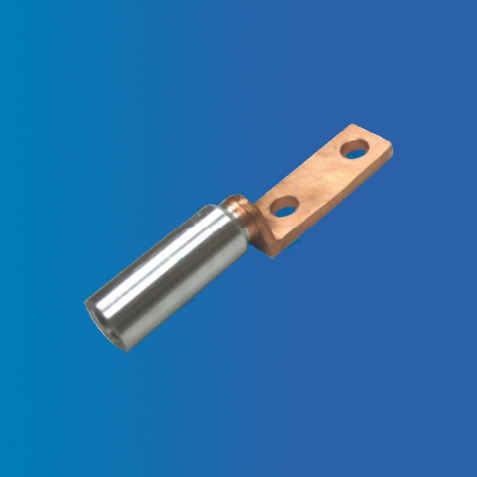

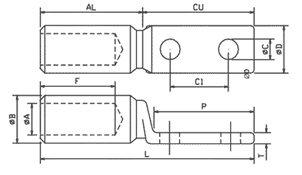

- • Copper Aluminium Bi Metal Lugs

- • Bimetallic Compression Reducers

- • Non Tension bi Metallic Compression Joints

- • Bimetallc Connector

- • Bi Metallic Pin Connectors

- • Bi Metallic Lugs with Centre Palm

- • Special Bi Metallic Lugs

- • Reverse Bi Metallic Lugs

- • Bimetallc Connector

- • Bi Metallic Lugs With Extended Palm

-

- • Ring Type Bi Metallic Lugs

- • Bimetallc Connector

- • Bi Metallic Lugs with Centre Palm

- • Tinned Copper Heavy Duty Cable Terminal Ends with Iinspection Slot

- • Copper Tube Terminal Light Duty

- • Crimping Type Tinned Copper Transformer Terminal Ends

- • Aluminium Tube Terminals Two Holes

- • Copper Tube Terminial Heavy Duty Long Barrel

-

- Contact

- Enquiry